Now there is a cheaper KC-120 electric rust remover on the market. Our company purchased one at our own expense and made the following disassembly analysis report with our mass-produced KC-120 electric rust remover:

Our company mass-produces KC-120

1. Motor differences

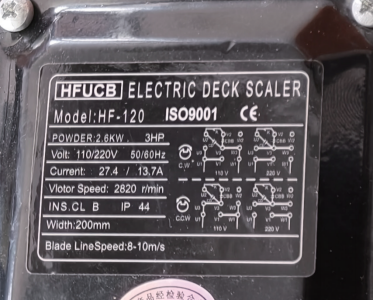

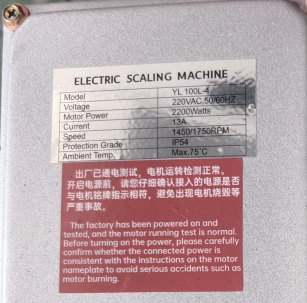

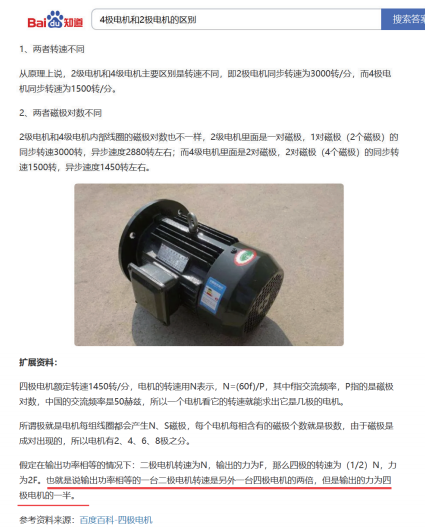

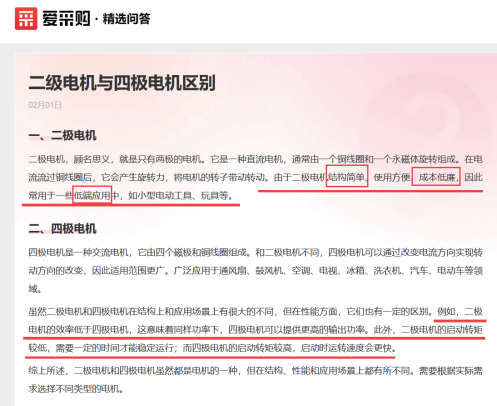

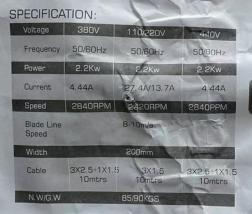

Our company uses a four-pole motor, while a certain company uses a nominal 2.6KW two-stage motor. The two are not only different in cost, but the bigger difference is the power generated by the output. Although the four-pole motor has a low speed, it has a single output. The power is indeed more than twice that of the two-pole motor. Dealers can also consult relevant information to judge which one is better or worse. For such rust removal application scenarios that require high power, our company believes that using a two-pole motor is not suitable.

Our KC-120 motor nameplate

2. Differences in cables

Our KC-120 (220v) uses 2x2.5mm² E (E is the ground wire) cable, and the factory length of the cable is 30 meters.

A certain company's KC-120 (220V) uses a nominal 3x1.5mm² cable with a measured length of 10 meters.

Let’s not discuss the price difference in specifications for the time being. In terms of the factory length of the cable, a certain company’s KC-120 is 20 meters shorter and the cost is about 140 yuan lower.

Moreover, a certain company does not equip marine waterproof plugs before leaving the factory, but only installs a waterproof socket on the cable, which costs 20 yuan less. Our company is equipped with both of them installed on the cable before leaving the factory.

Comparison of thickness measurements between the two

Comparison of specifications between the two

The nominal name of our cable is 2x2.5mm² E (E is the ground wire), and the nominal name of a certain company's cable is "3x1.5mm²". After disassembly, it was found that the nominal name of a certain company's cable was wrong, and it should actually be marked 2x1. 5mm² E (E is the yellow-green double-colored wire in the left picture of the ground wire) or 3G 1.5mm² (G represents the ground wire). This can be said to be an obvious misleading behavior to consumers, which shows the professionalism of a certain cable supplier. Do you have basic cable knowledge?

Comparing prices according to specifications, the cost of a certain company's 2x1.5mm² E cable is definitely lower than our company's 2x2.5mm² E cable. Correspondingly, the cable performance is also lower than our cables.

Our KC-120 cable is equipped with a cable protective sleeve. A certain company’s KC-120 cable is directly installed naked, and its safety is questionable.

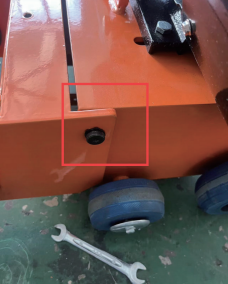

3. Differences in mechanical properties

Our KC-120 pulleys are scientifically arranged from large to small from the motor to the rust removal head. According to the knowledge of mechanical design, the motor pulley is larger than the rust removal head pulley, which can effectively amplify the rotational force of the rust removal head, just like a The large gear drives the small gear. When the large gear rotates once, the small gear has already rotated twice. Although the rotation speed of our four-pole motor is slower than that of the two-pole motor, according to the calculation of the transmission efficiency of the pulley, the transmission performance released to the rust removal head is much greater than that of the two-pole motor.

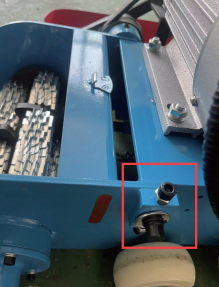

The three sets of pulleys of a certain company's KC-120 are exactly the same size. The kinetic energy of the rotation of the motor is released to the rust removal head. There is no optimization and consideration of mechanical design. The motor rotates once, and the rust removal head rotates once. Considering the friction between the rust removal head and the rust removal surface, the rotation speed will drop a lot and the rust removal efficiency will be lower.

Our KC-120 has the function of adjusting the belt tension. A certain machine is equipped with this function. Only a direct pin is used to connect the front shell and the rear shell of the machine. The belt cannot be adjusted.

The tightness of the belt plays a vital role in the transmission of the motor. If the belt is too loose, it will cause the belt to slip and the motor transmission will be insufficient. If the belt is too tight, it will cause increased belt wear and waste accessories and maintenance time.

With the use of the machine, the tightness of the belt is very important. One company has reduced the function of adjusting the belt tightness, and can only spend more money to replace the new belt to maintain the rust removal efficiency.

Our KC-120 has the function of adjusting the eccentricity of the rust removal head. For rust removal surfaces with different tilt angles, the angle can be adjusted by adjusting the eccentric shaft screw, so that the rust removal head is positioned to fit the rust removal surface. This kind of function is the original invention patent of our company KC-120.

A certain KC-120 does not have the above adjustment function.

Our new rust removal head is designed with no dead corners. The previous rust removal head had a dead corner in the middle of the rust removal head, and the rust remover still needed to be pushed to remove the rust. The new design has completely avoided this phenomenon, with no dead corners.

The rust removal head of a certain company's KC-120 still uses our old design, which has dead corners for rust removal and does not have its own design thinking. This shortcoming alone makes the rust removal efficiency lower than that of our rust remover.

After measurement by a professional hardness tester, the carburizing hardness of the shaft pin of our rust removal head is HRC40±2, and the hardness of the shaft pin of a certain company's rust removal head is HRC30±2. The lower the hardness, the less durable it will be.

Moreover, the shaft pin of a certain company's rust removal head does not have a designed positioning step. It is easy to become loose after long-term use. The service life is much lower than that of our accessories, and the installation is also very inconvenient.

Our company is responsible for the above measurement data.

The shaft pin of the rust removal head of a certain company is not galvanized or the thickness of the galvanization is much lower than that of our company, and the production cost is also lower than that of our company.

After measurement with a professional hardness tester, the carburizing hardness of our rust-removing gears is HRC50-55, and the carburizing hardness of a certain company’s rust-removing gears is HRC50-55.

The front cover of our rust remover is designed with a quick opening and closing buckle. The front cover of a certain rust remover is directly fixed with rotating screws.

Regardless of whether the mechanical design above is better or worse, the production cost of a certain company's design is definitely lower than the production cost of our company.

4.Other aspects

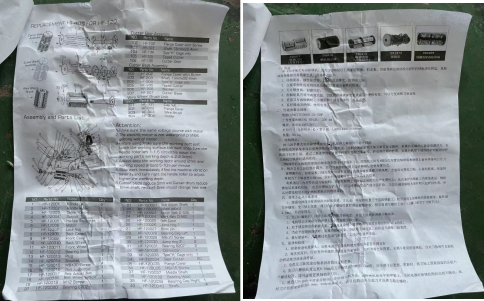

The instruction manual of a certain company's KC-120 has completely stolen the instruction manual of our company's old KC-120. The product pictures and product explosion diagrams are from our company's old instruction manual. They are no longer used due to backward patterns and individual data labeling issues. Our company expresses indignation at such blatant plagiarism, reserves the legal right to safeguard legitimate intellectual property rights, and plans to pursue its legal responsibility.

In the labeling of a certain KC-120 manual, we can see several obvious labeling errors. For example, the motor power does not match the actual motor nameplate. Such unprofessional behavior makes people worry about the quality of its product.

Our KC-120 rust remover comes with a set of installation tools, a screwdriver, a wrench, a belt set, and an Allen wrench. The cost is about 25 yuan.

When a certain KC-120 was unboxed, only an instruction manual and an unknown bolt component were found, and no installation tool set was included.

Our KC-120 rust remover is packed in wooden boxes with beautiful color printing and clear specifications.

A certain company's KC-120 rust remover is packed in wooden boxes, which are only white boards, not beautiful and not professional enough, and the specifications are not obvious.

Our wooden boxes are designed with feet, making them easy to transport with a forklift.

English

English  English

English 中文简体

中文简体

No. 108, Beltway Avenue, automobile andmotorcycleindustrial park, Yühuan, Zhejiang, China.

No. 108, Beltway Avenue, automobile andmotorcycleindustrial park, Yühuan, Zhejiang, China.

+86-0576-87225288/+86-576-80735186

+86-0576-87225288/+86-576-80735186 +86-17816566269/86+18957645051

+86-17816566269/86+18957645051